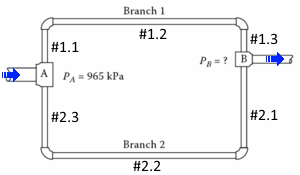

More often than not, engineers have only one choice in the duct geometry design. The only choice left is to design an irregular (polygon) shaped ductwork that will fit within the roof truss configuration as shown in the picture below. Judgement is required for this kind of design application. Do you call it an “integration or innovation” solution to suit available space?

Obviously, one cannot use a conventional ductulator for this kind of duct geometry. So, how to size an irregular (polygon) shaped ductwork like this one?

Fortunately, the fundamental theory of duct sizing allows us to size an irregular shaped duct. For non-circular duct, the hydraulic diameter (Dh) is given by:

It is important to note that the so-called hydraulic diameter (Dh) as expressed is applicable to both circular and non-circular ducts.

For the polygon shaped ductwork as shown in the picture above, the tedious task is to find the cross section area and perimeter of the duct. In terms of design calculations, this accounts for the main difference between an irregular (polygon) shaped duct and a conventional (round, rectangle, oval) duct geometry. At this point of the calculations, it is best to use some design tools (e.g., AutoCAD, polygon calculation software, etc.) that allow you to calculate the cross section area and perimeter of a polygon. This will save you a lot of time.

It is not the intention of this post to illustrate the calculations of duct pressure drop, Reynolds Number and darcy’s friction factor, etc. The formula for duct sizing is documented in the ASHRAE Fundamentals.

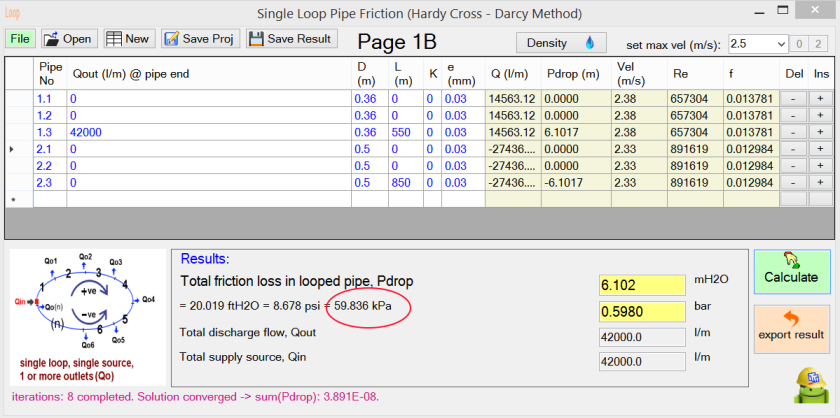

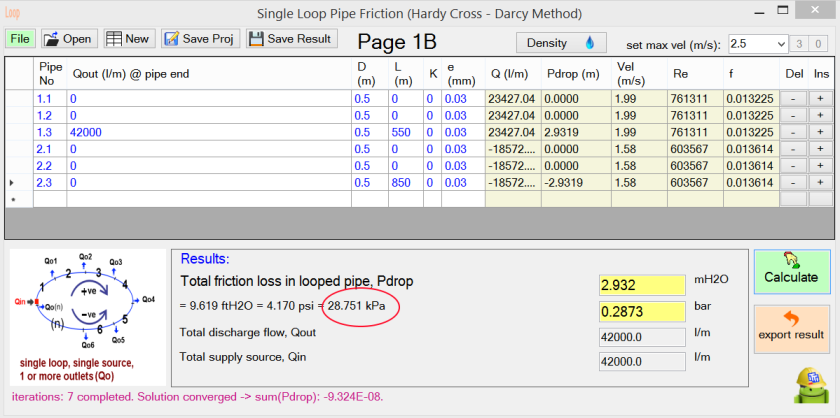

In short, I will use some design tools such as aDuctulator (for Android OS) for duct sizing of any shape as illustrated in the example below.

The following results are obtained using aDuctulator:

(1) Find cross section area and perimeter of the irregular shaped duct.

(2) Find flowrate or friction loss rate.

(3) Save/Print results

————————————-

.TT pocketEngineer softDesign

.TT pocketEngineer softDesign